What is Electron Beam Curing Technology?

An environmentally friendly, highly efficient, and performance-superior civilian non-power nuclear technology.

The electron is a fundamental particle. In solids, electrons are responsible for conducting electric charge, thereby generating electric current. When using an electron beam to process materials, particles loaded on the cathode are released, accelerated, and focused into a fine beam. Upon striking the material, the electron beam releases energy. The material absorbs this energy and converts it into heat. Due to the high intensity of the beam at the focus, a portion of the molten material evaporates. This creates a fine steam tube that penetrates into the material, enabling welding or curing depths of up to hundreds of millimeters.

The application of electron beam technology spans multiple industries, leveraging its unique ability to provide precise and controllable energy concentrations for a variety of applications, ranging from aerospace, military research, micro-machining to industrial processes and materials science.

Curing, refers to the process of liquid coatings transforming into solid materials.

Currently, the more common curing processes in China are thermal curing and ultraviolet (UV) curing. EB electron beam curing is a new curing technology that has been developed based on UV curing. EB is a revolutionary curing technology, known as the most efficient, environmentally friendly, and clean curing technology to date. It can achieve 99% high cross-linking of coatings in milliseconds, saving 95%-99% of energy consumption compared to other curing methods, and significantly increasing production efficiency. Most importantly, EB is a food-grade safe curing technology. It can cure without the need for chemical cross-linking agents or photoinitiators during the production process, truly eliminating VOCs (volatile organic compounds) from the source of materials and saying goodbye to solvents completely.

EB electron beam curing endows panel coatings with superior physical properties.

1.High Barrier Properties Resulting from Dense Surfaces

- Yellowing Resistance: External oxygen finds it hard to permeate, and ultraviolet rays struggle to penetrate; (Application scenarios: Building exterior walls, balcony spaces)

- Easy to clean: not prone to staining or bacterial attachment; (Application scenarios: Kitchens, schools, hospitals)

- High performance: High hardness, wear-resistant, scratch-resistant, and resistant to chemical reagents. (Application scenarios: Flooring materials, high-end laboratories)

- Low odor: complete reaction, no seepage of substrate odors; (Application scenarios: Bedrooms, children's spaces)

2.The Application of EB Electron Beam Curing Technology in the Panel Industry

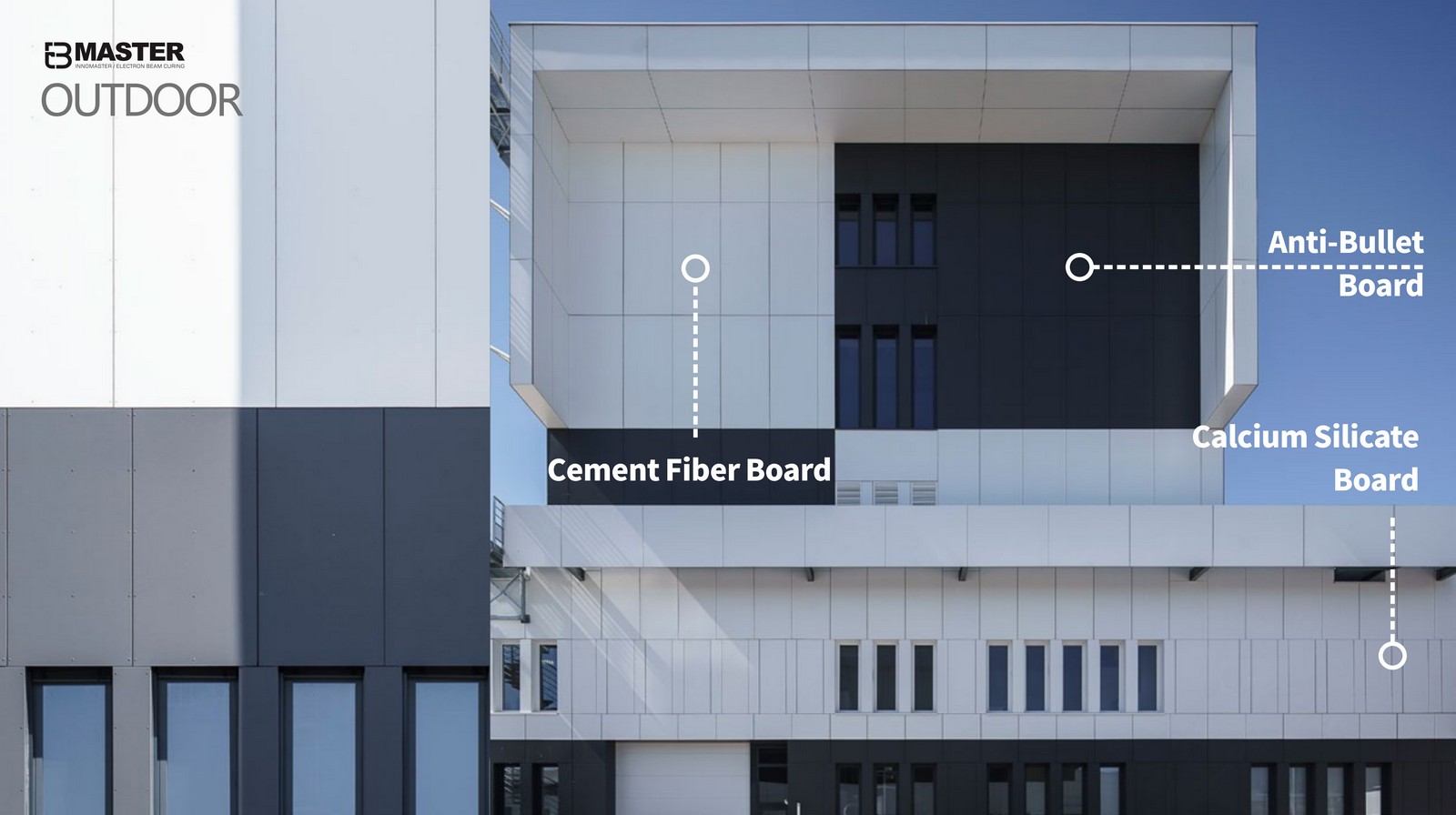

OUTDOOR

INDOOR

INNOMASTER Wall Panel Series Fully Upgraded with Electron Beam Curing

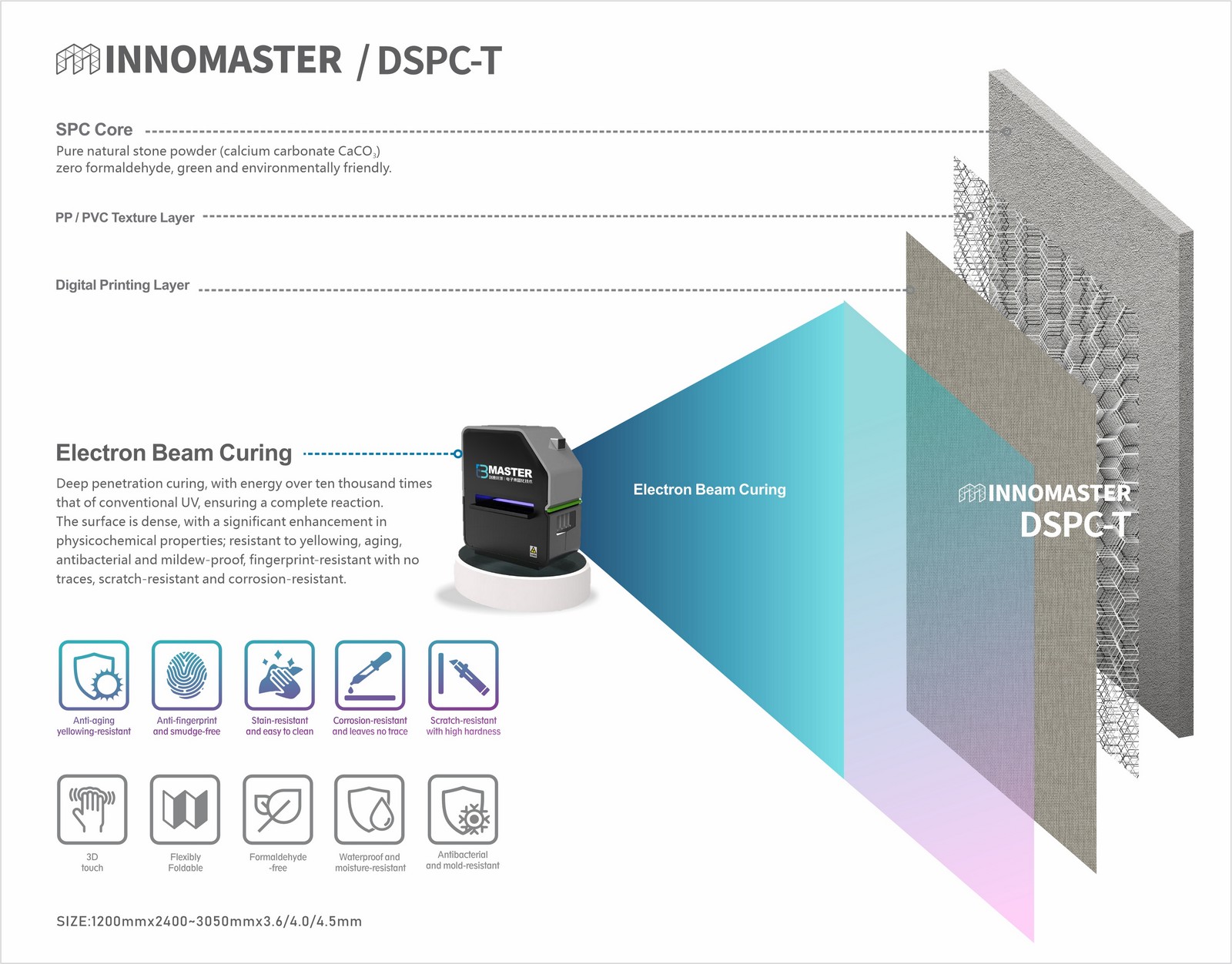

1.SPC Wall Panel

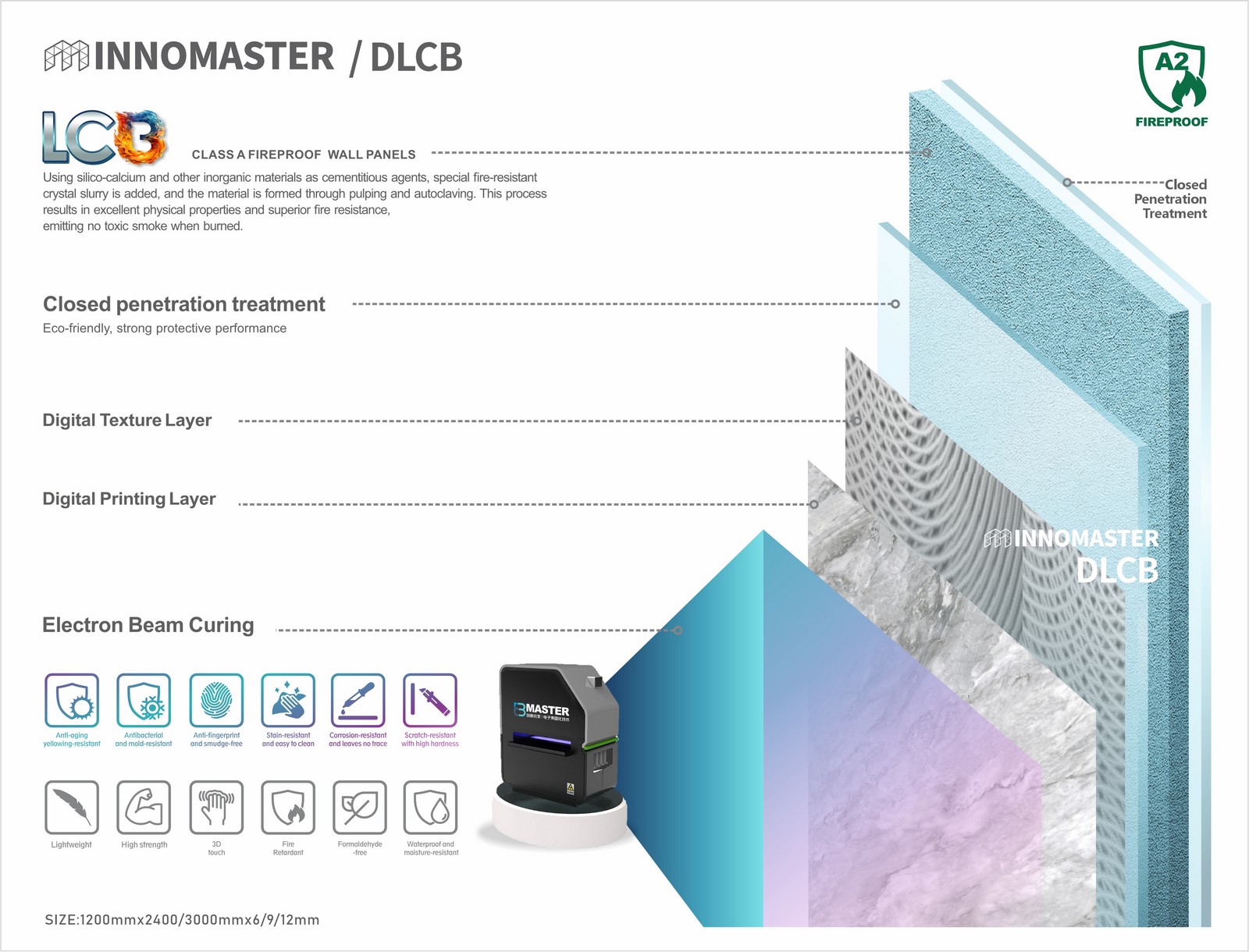

2.LCB FIREROOF WALL PANEL

INNOMASTER EB/MASTER Electron Beam Curing Production Line

producing 2 million square meters of EB wall panels and 2 million square meters of EB flooring annually.